The” Centro di Volo a Vela del Politecnico di Torino CVT”

(The Experimental Soaring Centre of the Turin Institute of Technology CVT)

The “Centro di Volo a Vela del Politecnico di Torino” (CVT), was

founded in May 1952 by a group of seven enthusiasts who wanted to

challenge the design and construction of sailplanes as done before WWII by the German Akafliegs (Akademische Fliegergruppe) and the Royal Polytechnic of Milan.

Alberto and Piero Morelli, together with Attilio Lausetti, Franco and Mario Ferrero, Luigi Marazzi Ghisleri and Aldo Conti, founded the CVT with the statutory objective of designing and building sailplane prototypes and equipment related to them. The Centre was housed in a small corner of the Aviation Laboratory in the Valentino Castle, where the Polytechnic was located. The first design proposal came out the pencils of the Morelli Brothers and construction of the first prototype started in that same month.

Because of a lack of finance, each member had to contribute 30.000 Italian Lira to provide start up expenses. A few months later some substantial help came from the Aviation Division of FIAT and from the Italian Civil Aviation Authority. The Italian Air Force also offered their help by providing a band saw and other pieces of machinery for wood-working. Soon after that, many students joined the CVT, most of them coming from model building.

For Aldo Conti and Alberto and Piero Morelli, the CVT activity became the most important activity inside the Polytechnic in Turin.

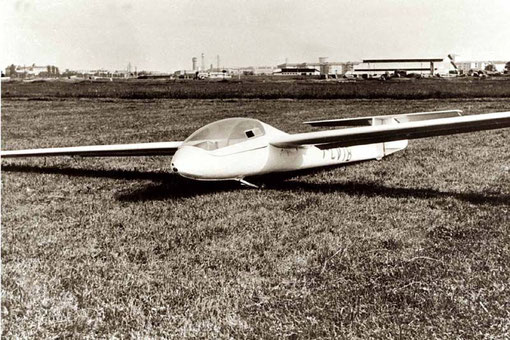

CVT 1 Zigolo (Bunting)

The first project of CVT was given the name of CVT 1 Zigolo and it took 16 months to build, from May 1952 to October 1953.

The idea was to build a sailplane of medium characteristics, low cost, small in size and easy to rig and fly. The mono-spar wing was built in a single piece with the leading edge planked with plywood. Both wing and tail-planes were fabric covered and a cantilevered high wing configuration was adopted for safety reason in case of out landing. The fuselage, built in the classical way with formers and stringers, was completely planked with plywood and provided with a small landing wheel as well as a wooden skid with rubber shock absorbers. The cockpit was in front of the wing and a Plexiglas canopy offered the pilot excellent visibility. All controls were standard and pedals were adjustable in flight. The airbrakes were designed in a rather unique way:

on demand a plate came out on each side of the fuselage; however the system, which was successful in the wind tunnel, failed during the actual flying test because the plates did not open to a full 90°, as they should have done. Rather than trying to solve the problem and improve the system, the Morelli’s decided to use traditional spoilers on the top surface of the wing.

In July 1953 the CVT Zigolo, not yet completed, was exhibited in the Hall of the Science and Technique Palace in Turin.

The construction of the Zigolo was supervised by the Italian Civil Aviation Register, which requested a number of tests, all successfully passed by the CVT 1 Zigolo.

The final testflight took place at the Aeritalia Airport of Turin on the 7th of April 1954, performed by the famous test pilot Adriani Mantelli, who after landing from the test, declared that the Zigolo was the best Italian sailplane of those days.

CVT2 Veltro (Greyhound)

The CVT 1 Zigolo was not completed when Alberto Morelli designed and started building the second prototype called CVT 2 Veltro. This was built in only 8 months between November 1953 and June 1954.

It was designed as a high performance competition sailplane, introducing several innovations with remarkable features, such as the reclined seat, laminar wing airfoil, the T-tail, retracting undercarriage, and in the first version the “Orthocinétique” control.

The reclined seat allowed a considerable reduction in cross section of the fuselage, with consequent reduction of the total aerodynamic drag.

The use of laminar wing airfoils: NACA 6 series, was one of the first in the word, second only to the American glider Ross and Johnson RJ5.

The T-tail, with the elevator placed above the vertical fin, was a world-wide innovation (unless proved otherwise) and it was meant to reduce drag , to escape the wing wake and to reduce damages in case of out landing.

The retracting undercarriage was quite unusual and consisted of twin small diameter wheels and twin shock absorbers.

The Orthocinétique control had never been tested in sailplanes and for the preliminary tests a normal stick and pedals were installed.

The Orthocinétique control system was designed to obtain the following advantages:

-A better co-ordination of control movements, all being made by hands and more instinctive. The wheel rotations about the 3 axis had the same directions as the sailplane rotations about the same axis.

-The pilot’s feet were free and could have been employed for other purposes, such as flap control and undercarriage retraction.

-The flap/air brake offered excellent landing when rotated to 60° or more. This system provided a smooth wing surface, free of any disturbance as with dorsal spoilers.

To solve a serious rudder lock problem in side slips, a kind of “double slotted” rudder was fitted, with good effects on control in the yawing plane.

The wing was in three pieces, a seven metre centre-section and two outer parts of four metre each. The plywood covering was not continuos around the leading edge, but consisted of two separate panels with the leading edge made from balsa wood, glued to the auxiliary spar and accurately shaped.

The fuselage Structure consisted of four stringers and circular formers planked with plywood, the wing-fuselage connection being made by means of four tapered pins. The tail-plane was a similar structure to the wing.

The first test flight was successfully performed by Antonio Angeloni on 9 September 1954 in Torino. From February to September 1955 the CVT 2 Veltro was based at the Gliding Center of the Italian Air Force in Guidonia airport, near Roma where Alberto Morelli was on Military duties.

During that period many improvements to the sailplane were carried out including a modification to the retractable undercarriage.

On March 3 1956, Alberto Morelli in wave flight over the mountains of the Susa Valley exceeded an altitude of 7.000 metres in the Veltro and in August 1957 also in the Veltro he covered a distance of 300 Km flying from Rieti to Barletta. These results were the best achievements for the Italian Gliding of those days.

Both CVT 1 Zigolo and CVT 2 Veltro were invited to participate in the first International Aviation Exhibition in Venezia Lido at the end of July 1955, where the Veltro was particularly appreciated for its elegant shape.

Unfortunately, for various reasons, the Veltro could not attend the World Championships of 1954 and 1956 and so it missed the chance to be known at international level for its innovative and sometimes unique characteristics.

M-100

In January 1956 the Italian Aero-Club, in order to increase the number of sailplanes for the Italian gliding clubs, announced a competition among all Italian sailplane designers and manufacturers to

select a modern single seat glider. According to the announcement of the competition, the sailplane should have been first of all low cost, strong and easy to repair and inspect, with characteristics

for both sport activities and training for the achievement of C pilot licence. The quotation was requested for a single prototype and for a series of ten sailplanes.

On 14th April 1956 Alberto and Piero Morelli sent their proposal enclosing the drawing of a sailplane named M-100. That proposal was well accepted by the Aero Club who placed immediately the order

for the prototype which was built by the company Nicolotti & Figli, specialised in wood work.

To keep the cost down the Morellis thought to limit the size of the sailplane, but fixing as a target an efficiency of 30 and a wing loading of 20 Kg/ m2.

As the wing load varies with the wing span and the aspect ratio, they choosed a wing span of 14 metres which resulted in a low weight and so in a low cost.

The fuselage cross section was designed following the experience of the Veltro with the reclined seat even if not as much as in the Veltro.

The tail plane was also designed based on the experience of the Veltro to reduce the damages in case of out landing, but the rudder surface was increased passing over the elevator to provide a great

aerodynamic compensation surface.

The M-100 was built under the supervision of the members of CVT in only six month as committed in the terms of contract, but actually the time was not enough to thoroughly fix the performance of the

sailplane.

When the M-100 was finished it was sent to the airfield in Rieti, where the test pilot Quirino Scano performed several tests which revealed a number of problems which were fixed by Alberto Morelli

during all 1957.

The most significant improvements were applied to:

-To the ailerons which were modified from the usual hinged type to a slotted type to improve their efficiency at small deflections

-To the rudder by eliminating the part exceeding the elevator to reduce the excessive aerodynamic compensation.

-To the spoilers which were replaced by two pairs of counter-rotating plates made by fibre glass and polyester resin to prevent suction at the high speed.

Besides these changes, the control cables were replaced by push-pull rods. and the solid rubber landing wheel was replaced by a pneumatic one.

CVT-4 Strale (Dart)

In 1955 the Centro di Volo a Vela del Politecnico di Torino, CVT designed and started the production of a new sailplane intended to become the improvement of the CVT2 Veltro. The carry out of this project took a great deal of time for the following reasons:

-The CVT laboratory was moved from the Valentino Castle to another site.

-The design of the Standard class sailplane requested a huge amount of time to modify the M-100 to M-100S.

The CVT-4 Strale was completed in July 1961 and it took part to the Italian Nationals in Perugia from August 1st to 14th.

The main differences of the Strale comparing with the Veltro were:

Wing:

- the wing span was increased from 15 metres to16,08 and the aspect ratio from 18 to 19,3 metres.

- Same airfoils, but without wash out and without wing tip bodies (salmons)

- The wing was built in two parts instead of three

- The ailerons were shorter

- There were no flaps, but counter-rotating plates like in M-100S

- The wing was in high configuration and not medium as in the Veltro

Fuselage:

- The cockpit was slightly higher to allow the pilot a less reclined position.

- There were no substantial differences between the two fuselagestructures.

Tail-plane:

- Same as in the last version of Veltro with double slotted rudder.

Landing undercarriage:

- Retractable skid as in the Veltro, but with single shock absorber and landing wheel.

The test flights and the Nationals in Perugia proved that the glider had excellent flying performance.

M-200

After completing the CVT-4 Strale the CVT started building the M-200 designed by Alberto Morelli. This two-seater glider was conceived for training as well as for sport activities.

The wood and fabric mono-spar wing was derived from the well tested

M-100S one. The wing span was increased from 15 to 18,5 meter and the aspect ratio from 17,1 to 19.

The fuselage had a shell structure reinforced by a few formers and stringers. The plywood covering consisted mainly of large pre-moulded double curvature panels (1/8” thickness).

The air brakes were similar to the M-100S, but with four instead of three counter-rotating plates for each wing. They were very powerful and could be pulled out with the least force at any speed.

All controls were push pull steel tubes. Only the rudder control circuit included a couple of straight steel cables.

The landing gear was a fix wheel of 365X150X100 with brake. Rubber shock absorbing front and tail skid.

The seats were staggered in the same way of the Australian ES 52 Kookaburra and the Swiss Spyr V, allowing both instructor and pupil good vision and the comfort of more elbow room.

The first flying test was made by Alberto Morelli in 1964 in Torino.

Four M-200 were produced in Italy by Avionautica Rio and later on the French company CARMAM bought the licence and built over 70 units till 1972 with the technical support of the Morelli Brothers. The M-200 was renamed Foehn and exported in many parts of the world.

It is still possible today to see the M-200 or Foehn successfully flying in one of the many Vintage Glider Rally in Europe and North America.

M-300

Last glider project of the CVT was named M-300 and it was designed by Alberto Morelli with the cooperation of his brother Piero, particularly regarding the extruded structures and the Redux bonding of wing fitting to spar.

The construction of four units started in the mid sixties by the CVT and financed by three Italian glider Pilots. Of the four only two were completed and the first prototype flew in May 1968.

The original design was a mixed structure made mainly of aluminium alloy

extruded profiles for the rectangular part of the wing, airbrakes, ailerons, horizontal tail and glass reinforced epoxy for the wing tips, fuselage, vertical tail and fairings.

For the difficulty and cost of the large size wing extrusions, the fully extruded wing structure was delayed. The two completed prototypes had a 7075 aluminium alloy wing spar machined for tapering, the rest of the wing had wooden ribs and thick plywood skin. Airbrakes, ailerons and horizontal tailplane were extruded. Their thickness was reduced from 2 mm to 0,8/0,5 mm by chemical milling.

The fuselage was made of wood, its nose was a glass-plastic moulding.

The wings were connected at the centre line by aluminium alloy fittings moulded, machined and Redux bonded to the spar.

To land a retractable wheel with rubber shock absorber in the tail skid.

The first prototype took part to the “Huit jours d’ Angers” in France in 1969

resulting 4th out of 55 competitors. Both prototypes were flown in several Italian Nationals.

The first prototype is exhibited in the Aeronautical Museum of the Politecnico of Torino.

Although the extruded wing box structure was successfully realised, the fully extruded wing was not.